bull nose end mill definition

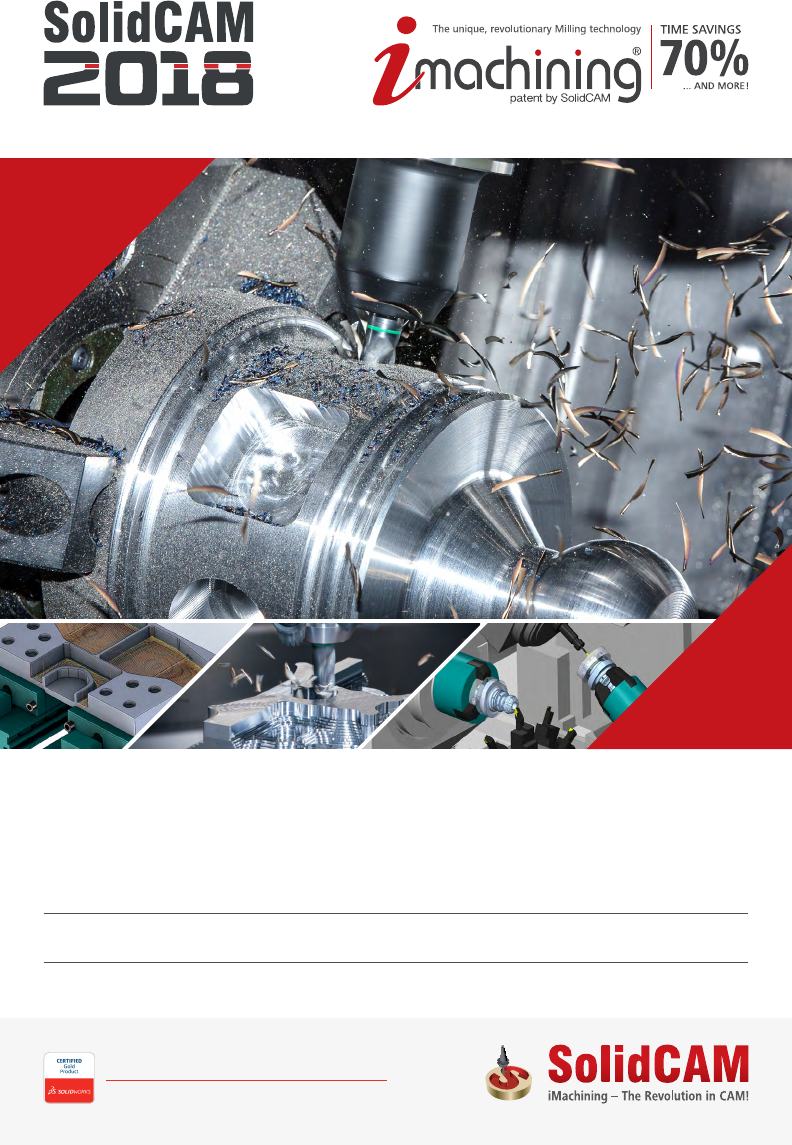

Moulds dies and blades milling are usual examples of this category. Browse discover thousands of brands.

Lag Angles Of The First Cutting Edge Download Scientific Diagram

An end mill is a type of milling cutter a cutting tool used in industrial milling applications.

. Often used for slotting and pocketing cuts in mold and die making they have a 90 profile and rounded corners which reduce flute breakage and chipping. Not all mills can cut axially. Meaning the flat on the bottom of the tool is the same diameter.

A bull nose cutter mills a slot with a corner radius intermediate between an end mill and ball cutter. The cutter diameter is often the first thing machinists look for when choosing a tool for their job. 625 shows WEBNHE performing up milling operation.

They are used for contour milling shallow slotting pocketing and contouring applications. To properly employ a ball nose end mill with no tilt angle and gain the optimal tool life and part finish follow the 2-step process. They only way we seem to be able to come close is using a conical mill zeroing out the radius and redefing the conical portion as a chamfer.

Ball nose mills have a radius at the bottom which makes for a nicer surface finish in your workpiece meaning less work for you as the piece wont need to be finished any further. Cliff rescue sparks childhood memory for one. Bull Nose End Mills Corner Radius Bull end mills are simply corner radius end mill cutters.

Dolphin Solid Carbide Ball Nose Endmill Dia 20mm and Overall length of 150mm. Were looking to have the ability to define an end mill with a chamfer instead of a radius bull nose tip. Corner radius end mill cutters have a stronger milling edge than square end mills so feed rates may be increased and yield longer tool life and greater productivity.

Ball Nose Milling Without a Tilt Angle. The material of workpieces by the bull nose end mills can be steel stainless steel and cast iron approx 55HRC. Mechanics of wavy-edge bull-nose helical end mill.

Youd still have basically zero SFM at the center of the ball end mill and a much less stiff cutter. All are center cutting allowing plunge cuts into a surface. These radius end mills are single ended tools used for making corner radii at the bottom of a milled shoulder.

Product DescriptionCutting terms conditions. 1 the definition of geometric parameters creating primary points. See similar products ADD TO CART Buy Now.

A ball end mill is constructed of a round cutting edge and used in the machining of dies and molds. Ugly way to go about it. December 17 2008 0926 AM.

This type of cutter has a full radius on the end. Looking for 45 degrees bull nose end mill please refer to our 2 flutes and 4 flutes bull nose end mill. With better heat and wear resistance than high-speed steel these cobalt steel end mills can run at higher speeds and provide better performance on hard material such as iron hardened steel titanium and tool steel.

A photograph of the investigated WEBNHE is shown in Fig. Ball Nose End Mills. Round inserts and concepts with radius are milling cutters used for roughing and semi-roughing while ball nose end mills are milling cutters used for.

We have a precise End Mills Definition. Read customer reviews find best sellers. Unlike conventional drill bits end mills have cutting teeth at the sides and tip of the millBall nose end mills or ball end cutters are constructed with a round cutting end and center cutting edges used for milling contoured surfaces slotting and pocketing.

Ball nose end mills are cutting tools used in milling applications such as profile milling tracer milling face milling and plunging. Ball-end or bull-nose end mills are mainly used for copying operations of complex surfaces the application being known as sculptured surface milling SSM. Known as one of famous Precision End Mills Manufacturers and Suppliers in Taiwan we have a wide range of products for sale.

For example it may be a 20 mm diameter cutter with a 2 mm radius corner. This type of tooling features flutes with no flat bottom rounded off at the end creating a ball nose at the tip of the tool. In the meantime tbaker the only compromise is to define it as a bullnose with the chord length of the bull radius matching the chamfer length.

See similar products ADD TO CART Buy Now. Its just another version of a bull-nose end mill. The silhouette is essentially a rectangle with its corners truncated by either a chamfer or radius.

I dont have much experience with this but it seems like if you have the room to run it a bull nose EM has got to be a better way to go for stiffness lower spindle RPM for a given SFM etc than a ball nose EM with the same radius. Those designed to cut axially are known as end mills. It is distinguished from the drill bit in its application geometry and manufacture.

Defining a chamfered end mill. A tool with larger radii can also be referred to as bull nose Ball Profile End Mills. There are also bull nose end mills these have radiused corners that are smaller than the radius of the cutter.

Corner Radius end. The geometric simulation involves. 2 flutes bull nose end mills and 4 flutes bull nose end mills you can choose the.

So I dont know if its a problem with the pass or the tool definition to make that work. A ball nose end mill is just another name for a ball end mill. Ball nose end mills are ideal for machining 3-dimensional contour shapes typically found in the mold and die industry the manufacturing of turbine blades and fulfilling general part radius requirements.

Made of cobalt steel these end mills have good heat and wear resistance so they can run at high speeds in hard material. Cobalt Steel Ball End Mills with Two Milling Ends. While a drill bit can only cut in the axial direction most milling bits can cut in the radial direction.

WIDIA Standard 4 Flute Solid Carbide Ball Nose Endmill Cutting Dia 16 mm by WIDIA. The ball has a radius with its center point at the center of the end mill. Ball end mills also known as ball nose end mills are used for milling contoured surfaces slotting and pocketing.

The minimum diameter shank of bull nose end mills is 4mm and the max. A ball end mill is not the same as a corner radiusbull nose end mill. R angle of bull nose end mills is 02 05 10 mm.

When one end wears out turn the tool around for a sharp edge. Echaintool Precision is definitely your good choice. The story in last Saturdays edition told how firefighters RAF and police helicopter crews the Barry Dock Lifeboat an ambulance crew and the coastguard rescued the boy who was wearing only a T-shirt and jeans from a cliff known as the Bull Nose between Porthkerry and The Knap Barry on Friday.

2 the rotation of primary points to create knots. A typical ball end mill.

The Insert Rotations A Cutter Xyz And Insert Uvw Coordinates Download Scientific Diagram

The Influence Of The Toolpath On Thin Floors Left Chatter Marks Download Scientific Diagram

4 Flute End Mills Carbide End Mill Store

Lag Angles Of The First Cutting Edge Download Scientific Diagram

Jelaskan Tentang Itu Cutter Dan Fungsinya

Lag Angles Of The First Cutting Edge Download Scientific Diagram

Popular Design For China High Speed Mills Tool Manufacturers And Suppliers Echaintool Precision

Illustration Of Undeformed Chip Thickness Modeling In Filleted End Download Scientific Diagram

Hrc55 Carbide Milling Cutter Tungsten Alloy Coating Drill Steel Cutting Tool Kit Woodworking Supplies Business Office Industrial Suneducationgroup Com

The Whole Procedure Of Cwe Extraction 1 Generation Of The Atsv 27 Download Scientific Diagram

Solidcam 2018 Modules Overview Solidcam Solidworks 8

Popular Design For China High Speed Mills Tool Manufacturers And Suppliers Echaintool Precision

The Insert Rotations A Cutter Xyz And Insert Uvw Coordinates Download Scientific Diagram